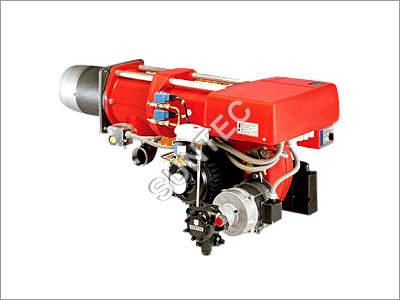

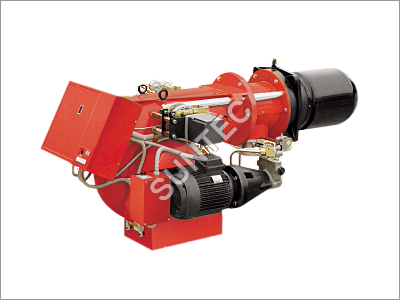

Modulating Dual Fuel Burner

Product Details:

X

Product Description

With the help of our experienced professionals, we are able to offer Modulating Dual Fuel Burner. These products are widely demanded in the market for their durability and efficient functioning. The burners are manufactured from supreme grade components and materials, as a result, these products are non-corrosive and need very low maintenance. Offered burner can be operated in various levels at a touch of a button plus it is installed with a safety device to avoid oil in circulation and to prevent pump seizure. To meet the various requirements of our valued customers, we offer the Modulating Dual Fuel Burner in various specifications.

Technical Data Of Modulating Dual Fuel Burner:

| Model | GI/EMME 1400 | GI/EMME 2000 | GI/EMME 3000 | GI/EMME 4500 | ||

| Burner operation mode | Modulating (with regulator and probes accessories) or two stage progressive | |||||

| Modulation ratio at max. output | 3:1 | |||||

| Servomotor | run time | type | SQM 10.16502 | |||

| s | 42 | |||||

Heat output | kW | 407/820-1540 | 581/1163-2325 | 872/1744-3488 | 1163/2350-4650 | |

| Mcal/h | 350/705-1324 | 500/1000-2000 | 750/1500-3000 | 1000/2021-4000 | ||

| Working temperature | oC min./max. | 0/40 | ||||

| Fuel / Air Data | ||||||

Oil | Net calorific value | kWh/kg | 11,8 | |||

| Viscosity | mm2/s ( cSt) | 4-6 (at 20oC) | ||||

| Delivery | kg/h | 34/69-130 | 49/99-197 | 74/148-296 | 99/199-394 | |

| Pump | type | TA2 | TA3 | TA4 | TA5 | |

| Delivery | kg/h | 336 (at 25 bar) | 546 (at 25 bar) | 706 (at 25 bar) | 1008 (at 25 bar) | |

| Atomised pressure | bar | 25 | ||||

| Fuel temperature | max oC | 60 | ||||

| Fuel preheater | NO | |||||

G20 | Net calorific value | kWh/Nm3 | 10 | |||

| Density | kg/Nm3 | 0,71 | ||||

| Gas delivery | Nm3/h | 41/82-154 | 58/116-232,5 | 87/174-349 | 116/235-465 | |

G25 | Net calorific value | kWh/Nm3 | 8,6 | |||

| Density | kg/Nm3 | 0,78 | ||||

| Gas delivery | Nm3/h | 47/95-179 | 68/135-270 | 101/203-406 | 135/273-541 | |

LPG | Net calorific value | kWh/Nm3 | 25,8 | |||

| Density | kg/Nm3 | 2,02 | ||||

| Fan | type | Centrifugal with reverse curve blades | ||||

| Air temperature | max oC | 60 | ||||

| Electrical data | ||||||

| Electrical supply | Ph / Hz / V | 3N/50/230-400 (+10%) | ||||

| Auxiliary electrical supply | Ph / Hz / V | 1/50/230 (+10%) | ||||

| Control box | type | LFL 1.333 | ||||

| Total electrical power | kW | 5,1 | 6,1 | 12 | 15,5 | |

| Auxiliary electrical power | kW | 1 | 1 | 1,5 | 2 | |

| Heaters electrical power | kW | -- | ||||

| Protection level | IP | 44 | ||||

| Pump motor electrical power | kW | 1,1 | 1,1 | 1,5 | 1,5 | |

| Rated pump motor current | A | 3 | 3 | 3,7 | 3,7 | |

| Pump motor start up current | A | -- | ||||

| Pump motor protection level | IP | 44 | ||||

| Fan motor electrical power | kW | 3 | 4 | 9 | 12 | |

| Rated fan motor current | A | 6,1 | 8 | 17 | 23 | |

| Fan motor start up current | A | 44,5 | 64 | 124,1 | 158,7 | |

| Fan motor protection level | IP | 44 | 44 | 44 | 55 | |

Ignition transformer | type | -- | ||||

| V1- V2 | 230 V - 2 x 6 kV | |||||

| I1 - I2 | 1,9 A - 35 mA | |||||

| Operation | Intermittent (at least one stop every 24h) | |||||

| Approval Emissions | ||||||

| Sound pressure | dB(A) | 85,4 | 88 | 92 | 93,1 | |

| Sound power | W | -- | ||||

Oil | CO emission | mg/kWh | < 50 | |||

| Grade of smoke indicator | No Bacharach | < 1 | ||||

| CxHy emission | mg/kWh | -- | ||||

| NOx emission | mg/kWh | < 250 | ||||

| G20 | CO emission | mg/kWh | < 100 | |||

| NOx emission | mg/kWh | < 150 | ||||

| Directive | 90/396 - 89/336 - 73/23 EEC | |||||

| Conforming to | EN 267 - EN 676 | |||||

| Certification | CE 0085AQ0712 | CE 0085AQ0712 | CE 0085AQ0712 | CE 0085AQ0712 | ||

| DIN 5G830/97 M | DIN 5G831/97 M | DIN 5G832/97 M | DIN 5G833/97 M | |||

Enter Buying Requirement Details