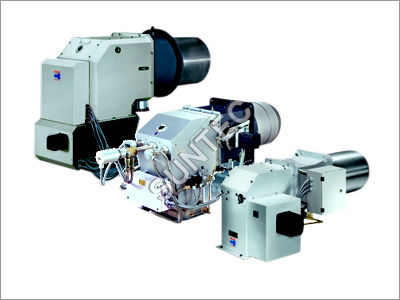

Dual Block Burners

Dual Block Burners Specification

- Product Type

- Dual Block Burners

- Usage

- Industrial

- Condition

- New

- Material

- Steel

Dual Block Burners Trade Information

- Minimum Order Quantity

- 1 , , Piece

- Supply Ability

- 10 Pieces Per Week

- Delivery Time

- 7 Days

About Dual Block Burners

Other details Of Dual Block Burners:

The industrial burners ER series are designed particularly for water tube boilers used in big civil installations and industrial processes with a remarkable thermal demand. These series allows to realize a modular and flexible combustion system adding a preparation fuel unit (regulation pressure group set, preheating/pumping oil station), a gas train, a control panel and a fan. It can also be used a preheated air as in the oil dia-thermic generators and other heat recovery systems. The modulating regulation always allows to reach a wide modulation ratio and optimal fluid dynamics conditions for a good combustion.

Technical Data Of Dual Block Burners:

| MODEL | ER 4 | ER 6 | ER 9 | ER 12 | ER 16 | ER 20 | ||

| Burner operation mode | Modulating | |||||||

|

| Natural gas | 1 : 6 | ||||||

| LPG | 1 : 5 | |||||||

| Light oil | 1 : 4 | |||||||

| Heavy oil | 1 : 3 | |||||||

| Servomotor | run time | type | MM 10004 - MM 10005 | |||||

| s | 30 | |||||||

|

|

| kW | 540/ | 840/ | 1250/ | 1750/ | 2350/ | 3000/ |

| Mcal/h | 464/ | 722/ | 1075/ | 1505/ | 2021/ | 2580/ | ||

|

| kW | 650/ | 1000/ | 1500/ | 2100/ | 2800/ | 3600/ | |

| Mcal/h | 559/ | 860/ | 1290/ | 1806/ | 2408/ | 3096/ | ||

|

| kW | 820/ | 1250/ | 1870/ | 2600/ | 3500/ | 4500/ | |

| Mcal/h | 705/ | 1075/ | 1608/ | 2236/ | 3010/ | 3870/ | ||

|

| kW | 1100/ | 1700/ | 2500/ | 3500/ | 4700/ | 6000/ | |

| Mcal/h | 946/ | 1462/ | 2150/ | 3010/ | 4042/ | 5160/ | ||

| Working temperature | °C min./max. | -15/60 | ||||||

| FUEL/AIR DATE | ||||||||

|

| Net calorific value | kWh/kg | 11,86 | |||||

| Kcal/kg | 10200 | |||||||

| Viscosity | mm2/s (cSt) | 4 - 6 (at 20°C) | ||||||

| Delivery | kg/h | 69/ | 69/ | 158/ | 219/ | 295/ | 379/ | |

| Fuel temperature | max. °C | 50 | ||||||

|

| Net calorific value | kWh/kg | 11,1-11,3 | |||||

| Kcal/kg | 9545-9720 | |||||||

| Viscosity | mm2/s (cSt) | 500 (at 50°C) | ||||||

| Delivery | kg/h | 98/ | 152/ | 223/ | 312/ | 420/ | 536/ | |

| Fuel temperature | max. °C | 140 | ||||||

| Atomised pressure | bar |

| ||||||

|

G20

| Net calorific value | kWh/Nm3 | 10 | |||||

| Density | kg/Nm3 | 0,71 | ||||||

| Gas delivery | Nm3/h | 54/ | 84/ | 125/ | 175/ | 235/ | 300/ | |

|

| Net calorific value | kWh/Nm3 | 8,6 | |||||

| Density | kg/Nm3 | 0,78 | ||||||

| Gas delivery | Nm3/h | 63/ | 98/ | 145/ | 203/ | 273/ | 349/ | |

|

| Net calorific value | kWh/Nm3 | 25,8 | |||||

| Density | kg/Nm3 | 2,02 | ||||||

| Gas delivery | Nm3/h | 25/ | 39/ | 58/ | 81/ | 109/ | 140/ | |

| Fan | type | centrifugal with reverse curve blades | ||||||

| Air temperature | max °C | 150 | ||||||

| ELECTRICAL DATA | ||||||||

| Electrical supply | Ph / Hz / V | 1/50-60/230 - (1/50-60/110 on request) | ||||||

| Control box | type | -- | ||||||

| Auxiliary electrical supply | kW | 1/50-60/230 - (1/50-60/110 on request) | ||||||

| Total current | A | -- | ||||||

| Protection level | IP | 54 | ||||||

| Ignition | type | ignition pilot burner | ||||||

| V1 - V2 | 230 V - 1x8 kV | |||||||

| I1 - I2 | 1,4 A - 30 mA | |||||||

| Operation | Intermittent (at least one stop every 24 h) - Continuos (at least one stop every 72 h) | |||||||

| APPROVAL EMISSIONS | ||||||||

| Sound pressure | dB(A) | -- | ||||||

| Sound power | W | -- | ||||||

|

Light | CO emission | mg/kWh | < 110 | |||||

| Grade of smoke indicator | N° Bacharach | < 1 | ||||||

| NOx emission | mg/kWh | < 185 | ||||||

| Heavy | CO emission | mg/kWh | Depending on the fuel amount | |||||

| Grade of smoke indicator | N° Bacharach | Depending on the fuel amount | ||||||

| NOx emission | mg/kWh | Depending on the fuel amount | ||||||

| G20 | CO emission | mg/kWh | < 100 | |||||

| NOx emission | mg/kWh | < 120 | ||||||

| Directive | 89/336 - 73/23 - 98/37 - 90/396 EEC | |||||||

| Conforming to | EN 267 - EN 676 | |||||||

| Certification | -- | |||||||

Reference conditions: Temperature: 20°C - Pressure: 1000 mbar - Altitude: 100 m a.s.l. - Noise measured at a distance of 1 meter.

Product Sopecification

OIL BURNER

Combustion head:

Forced draught oil burner with modulating operation and separate supplies, fully automatic, made up of:

- sheet-steel airlock painted with a front cover for access to the internal elements

- air dampers for air setting controlled by two Independent high precision servomotors

- combustion head fitted with:

- stainless steel end cone, resistant to corrosion and high temperatures

- pilot burner with gas train and ignition electrodes

- flame stability disk made up of axial swirlers

- flame shape regulation device

- photocell for flame detection

- minimum air pressure switch

- nozzle pipe

- safety nozzle valve

- valves group with safety oil valves

- automatic regulator of oil delivery controlled by a high precision servomotor

- maximum oil pressure switch on the return circuit

- pressure gauge on the delivery circuit

- pressure gauge on the return circuit

- electrical box with ignition transformerIP 54 electric protection level.

Conforming to

- 89/336/EEC directive (electromagnetic compatibility)

- 73/23/EEC directive (low voltage)

- 98/37/EEC directive (machinery)

- EN 267 (liquid fuel burners).

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Dual Block Burners Category

Industrial Dual Block Burners

Minimum Order Quantity : 1 Piece

Condition : New

Usage : Industrial

Material : MS

Pressure : High Pressure

Type : Others

Industrial Modulating Dual Fuel Burners

Minimum Order Quantity : 1 Piece

Condition : New

Usage : Industrial

Industrial Carbon Steel Dual Block Burners

Condition : New

Usage : Industrial

Material : MS

Pressure : Others

Type : Others

Send Inquiry

Send Inquiry