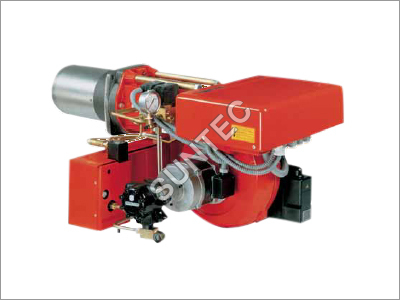

Two Stage Heavy Oil Burner

Two Stage Heavy Oil Burner Specification

- Condition

- New

- Type

- Others

- Usage

- Industrial

- Structure

- Others

- Pressure

- High Pressure

- Style

- Machine

- Material

- MS

Two Stage Heavy Oil Burner Trade Information

- Minimum Order Quantity

- 1 Piece

- FOB Port

- NA

- Payment Terms

- Cheque

- Supply Ability

- 100 Pieces Per Day

- Delivery Time

- 10-12 Week

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- wooden packing or Bubble packing as per customer request.

- Main Domestic Market

- All India

- Certifications

- EN 676

About Two Stage Heavy Oil Burner

Owing to our vast experience, we have been successful in catering to the needs of our clients by offering Two Stage Heavy Oil Burner. These products are highly appreciated by various industries for their efficient combustion and low fuel usage. A team of highly trained professionals manufactures these burners from premium quality components. These products are used in civil installations and in small and medium industrial plants. We examine the Two Stage Heavy Oil Burner before its delivery to offer our clients with flawless products.

Technical Data Of Two Stage Heavy Oil Burner:

| Model | PRESS 30 N | PRESS 45 N | PRESS 60 N | PRESS 100 N | ||

| Burner operation mode | Two stage | |||||

| Modulation ratio at max. output | 2 : 1 | |||||

| Servomotor | run time | type | LKS 210 | |||

| s | 5 | |||||

|

| kW | 85/171-342 | 114/205-513 | 171/342-684 | 171/342-684 | |

| Mcal/h | 73/147-294 | 98/176-441 | 147/294-588 | 245/421-980 | ||

| kg/h | 7,5/15-30 | 10/18-45 | 15/30-60 | 25/43-100 | ||

| Working temperature | oC min./max. | 0/40 | ||||

| Fuel / Air Data | ||||||

| NCV Heavy Oil | kWh/kg | 11,4 | ||||

| kcal/kg | 9800 | |||||

| Viscosity at 50°C | mm2/s (cSt) | 50 (150 with heavy oil kit) | 50 (500 with heavy oil kit) | |||

| Pump | Delivery | type | D67 | E4 | E6 | |

| kg/h | 65 (20 bar) | 110 (20 bar) | 200 (20 bar) | |||

| Atomised pressure | bar | 20 | ||||

| Fuel temperature | max.oC | 140 | ||||

| Fuel pre-heater | | YES | ||||

| Fan | type | Centrifugal with forward blades | ||||

| Air temperature | max. oC | 60 | ||||

| Electrical Data | ||||||

| Electrical supply | Ph/Hz/V | 1/50/230~(±10%) | 3N/50/400~(+10%) | 3/50/230~(+10%) | ||

| Auxiliary electrical supply | Ph/Hz/V | 1/50/230~(±10%) | ||||

| Control box | type | RMO | ||||

| Total electrical power | kW | 3,5 | 3,7 | 5,5 | 9,0 | |

| Auxiliary electrical power | kW | 0,33 | 0,45 | 0,5 | 0,5 | |

| Heaters electrical power | kW | 2,8 | 2,8 | 4,2 | 7 | |

| Protection level | IP | 40 | ||||

| Pump motor electrical power | kW | | ||||

| Rated pump motor current | A | | ||||

| Pump motor start up current | A | | ||||

| Pump motor protection level | IP | | ||||

| Fan motor electrical power | kW | 0,37 | 0,45 | 0,75 | 1,5 | |

| Rated fan motor current | A | 2,9 | 1,9-1,1 | 2,9-1,7 | 6-3,5 | |

| Fan motor start current | A | 9,5 | 9,5-5,5 | 14-8 | 28-16 | |

| Fan motor protection level | IP | 54 | ||||

|

| type | -- | ||||

| V1 - V2 | 230 V - 2x6,5 kV | |||||

| I1 - I2 | 2 A - 35 mA | |||||

| Operation | | Intermittent (at least one stop every 24 h) | ||||

| Approval Emissions | ||||||

| Sound pressure | dB (A) | 75 | 78 | 81 | 83 | |

| Sound power | W | -- | ||||

| CO emission | mg/kWh | < 50 | ||||

| Grade of smoke indicator | N Bacharach | < 5 | ||||

| CxHy emission | mg/kWh | -- | ||||

| NOx emission level | mg/kWh | < 650 | ||||

| Directive | | 73/23 - 89/336 - 98/37- 92/42 EEC | ||||

| Conforming to | | EN 267 | ||||

| Certification | | -- | ||||

Reference conditions:

- Ambient temperature: 20°C

- Barometric pressure: 1013.5 mbar

- Altitude: 100 meters a.s.l.

- Noise measured at a distance of 1 meter.

Burner:

Monoblock forced draught heavy oil burner with two stage operation, fully automatic, made up of:

- Air suction circuit lined with sound-proofing material

- Fan with forward curve blades, high performance pressure levels

- Air damper for air setting controlled by a servomotor

- Starting motor at 2800 rpm, three-phase 400V with neutral, 50Hz (single-phase, 230V and 50Hz for the 30 N model)

Combustion head, that can be set on the basis of required output, fitted with:

- stainless steel end cone, resistant to corrosion and high temperatures

- ignition electrodes

- flame stability disk

- filter

- pressure regulator

- connections for installing a pressure gauge and vacuometer

- Oil pre-heater equipped with a filter with sheath for thermometer, a setting thermostat and two safety thermostats

- Valve unit with an check valve and two delivery oil valves

- Oil delivery gauge

- Photocell for flame detection

- Microprocessor-based flame control panel, with diagnostic functions

- Slide bars for easier installation and maintenance

- Protection filter against radio interference

- IP 44 electric protection level.

Conforming to:

- 89/336/EEC directive (electromagnetic compatibility)

- 73/23/EEC directive (low voltage)

- 92/42/EEC directive (performance)

- 98/37/EEC directive (machinery)

- EN 267 (liquid fuel burners).

Standard equipment:

- 2 flexible pipes for connection to the oil supply network

- 2 gaskets for the flexible pipes

- 2 nipples for connection to the pump

- 4 screws for fixing the burner flange to the boiler

- 1 thermal screen

- 2 nozzles

- 2 slide bar extensions (for the extended head models)

- Instruction handbook for installation, use and maintenance

- Spare parts catalogue.

Available accessories to be ordered separately:

- Nozzles

- Spacer kit

- Sound-proofing box

- Self cleaning filter

- Heavy oil kit

- Cartridge filter

- Thermostat

- PC interface kit.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Heavy Oil Burners Category

Modulating Heavy Oil Burner

Minimum Order Quantity : 1 Pcs Piece

Usage : Industrial

Style : Machine

Condition : New

Material : MS

Structure : Others

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free