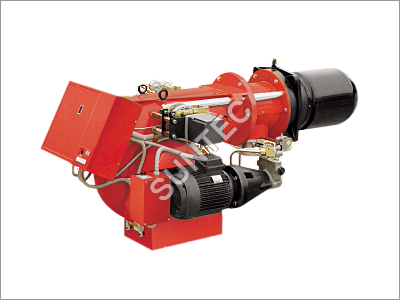

Low Nox Dual Fuel Burner

Low Nox Dual Fuel Burner Specification

- Color

- Red

- Size

- Standard

- Usage

- Industrial

- Product Type

- Low Nox Dual Fuel Burner

- Condition

- New

- Material

- Steel

Low Nox Dual Fuel Burner Trade Information

- Minimum Order Quantity

- 10 Pieces

- Supply Ability

- 10 Pieces Per Week

- Delivery Time

- 7 Days

About Low Nox Dual Fuel Burner

We are a profound industry engaged in supplying superior quality Low NOx Dual Fuel Burner. These products are manufacture by qualified professionals at our vendors base. High-grade components and materials are used to manufacture these products. These products are widely used in various industries for their easy to install & operate functions. The Low NOx Dual Fuel Burner is available in various specifications to meet the demands of our esteemed customers.

Technical Data Of Low Nox Dual Fuel Burner:

| Model | RLS 300/BP MX | RLS 400/BP MX | ||

| Burner operation mode | two stages light oil - two stages progressive/modulating gas | |||

| Modulation ratio at max. output | 1 3 (light oil) / 1 4 (gas) | |||

| Servomotor | type | SQM 10 | ||

| run time | s | |||

| Heat output | kW | 600/1250 - 3650 | 1000/2000 - 4500 | |

| Mcal/h | 516/1075-3139 | 860/1720-3870 | ||

| Working temperature | oC min./max. | 0/60 | ||

| Fuel / air data | ||||

Light Oil | net calorific value | kWh/kg | 11,86 | |

| density | kg/l | 0,82 | ||

| viscosity at 20oC | mm2/s (cSt) | 4-6 | ||

| delivery | kg/h | 50/105-308 | 84/169-380 | |

| Pump | type | TA2 | ||

| delivery | kg/h | 340 (20 bar) | ||

| Atomised pressure | bar | 12 | ||

| Fuel temperature | max. oC | 50 | ||

| Fuel pre-heater | NO | |||

| | net calorific value | kWh/Nm3 | 10 | |

| density | kg/Nm3 | 0,71 | ||

| gas delivery | Nm3/h | 60/125-365 | 100/200-450 | |

| | net calorific value | kWh/Nm3 | 8,6 | |

| density | kg/Nm3 | 0,78 | ||

| gas delivery | Nm3/h | 70/145-424 | 116/232-523 | |

| | net calorific value | kWh/Nm3 | ||

| density | kg/Nm3 | |||

| gas delivery | Nm3/h | |||

| Fan | type | reverse blade fan wheels | ||

| Air temperature | max oC | 60 | ||

| Electrical data | ||||

| Electrical supply | Ph/Hz/V | 3/50/230-400 (+10%) | 3/50/400 (+10%) | |

| Auxiliary electrical supply | Ph/Hz/V | 1/50/430 (+10%) | ||

| Control box | type | LFL 1.333 | ||

| Total electrical power | kW | 6 | 9 | |

| Auxiliary electrical power | kW | 1,5 | 1,5 | |

| Heaters electrical power | kW | |||

| Protection level | IP | 54 | ||

| Pump motor electrical power | kW | 1,1 | ||

| Rated pump motor current | A | 3,7 | ||

| Pump motor start up current | A | 24 | ||

| Pump motor protection level | IP | 55 | ||

| Fan motor electrical power | kW | 4,5 | 7,5 | |

| Rated fan motor current | A | 9,1-15,8 | 17,5 - 30 | |

| Fan motor start up current | A | 51-86 | 113 - 195 | |

| Fan motor protection level | IP | 55 | ||

| Ignition transformer | type | N.A. | ||

| V1 - V2 | 230 V - 2 x 5 kW | |||

| I1 - I2 | 1,9 A - 35 mA | |||

| Working | intermittent (1 stop each 24 h) | |||

| Emissions | ||||

| Sound pressure | dB (A) | 83 | 85 | |

| Sound power | W | N.A. | ||

| Light Oil

| CO emission | mg/kWh | < 10 | |

| grade of smoke indicator | No Bacharach | < 2 | ||

| CxHy emission | mg/kWh | < 2 | ||

| NOx emission | mg/kWh | < 185 | ||

| G20 | CO emission | mg/kWh | < 10 | |

| NOx emission | mg/kWh | < 80 | ||

| Approval | ||||

| Directive | 90/396 - 89/336 - 73/23 EEC | |||

| Conforming to | EN 267 - EN 676 | |||

| Certification | CE in progress | |||

Product Specification Of Low Nox Dual Fuel Burner:

Burner:

Monoblock forced draught gas burner with two stage progressive or modulating operation, fully automatic, made up of:

- Fan with reverse curve blades high performance with low sound emissions

- Air suction circuit lined with sound-proofing material

- Air damper for air setting controlled by a high precision servomotor

- Air pressure switch

- Fan starting motor at 2800 rpm, three-phase 230/400 - 400/690 V with neutral, 50Hz

- Low emission combustion head, that can be set on the basis of required output, fitted with:

- stainless steel end cone, resistant to corrosion and high temperatures

- ignition electrodes

- flame stability disk

- Maximum gas pressure switch, with pressure test point, for halting the burner in the case of over pressure on the fuel supply line

- Module for air/fuel setting and output modulation with separated PID control of temperature or pressure, available as accessory for RLS/BP MX model

- Flame control panel for controlling the system safety

- Ionization probe for flame detector

- Star/triangle starter for the fan motor (version with motor electrical power 7,5 kW)

- Main electrical supply terminal board

- Burner on/off switch

- Auxiliary voltage led signal

- Burner working led signal

- Contacts motor and thermal relay with release button

- Motor internal thermal protection

- Motor failure led signal

- Burner failure led signal and lighted release button

- Emergency button

- Coded connection plugs-sockets

- Burner opening hinge

- Lifting rings

- IP 54 electric protection level

- Gears pump for high pressure fuel supply

- Pump starting motor

- Oil safety valves

- Three oil valves (1st and 2nd stage 3nd safety valve)

- Flame control panel

- UV photocell for flame detection

- Burner on/off selection switch

- Oil/Gas selector

- Flame inspection window

- Burner opening hinge.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Dual Fuel Burners Category

Dual Fuel Burner

Minimum Order Quantity : 1 Piece

Color : Red

Usage : Industrial

Product Type : Dual Fuel Burner

Condition : New

Material : Steel

Two Stage Dual Fuel Burner

Minimum Order Quantity : 1 Piece

Color : Red

Usage : Industrial

Product Type : Two Stage Dual Fuel Burner

Condition : New

Material : Steel

Modulating Dual Fuel Burner

Minimum Order Quantity : 1 , , Piece

Color : Red

Usage : Industrial

Product Type : Modulating Dual Fuel Burner

Condition : New

Send Inquiry

Send Inquiry